Flow Rate Calculator

Calculating flow rate is a fundamental operation in various fields, including engineering, chemistry, and physics. It is essential for understanding how fluids, gases, or other substances move through a system, pipeline, or conduit. The flow rate, often represented by the symbol Q, is the volume of fluid that flows through a given surface per unit time. It is commonly measured in cubic meters per second (m³/s) or liters per second (L/s) for liquids, and cubic meters per second (m³/s) or standard liters per minute (SLM) for gases.

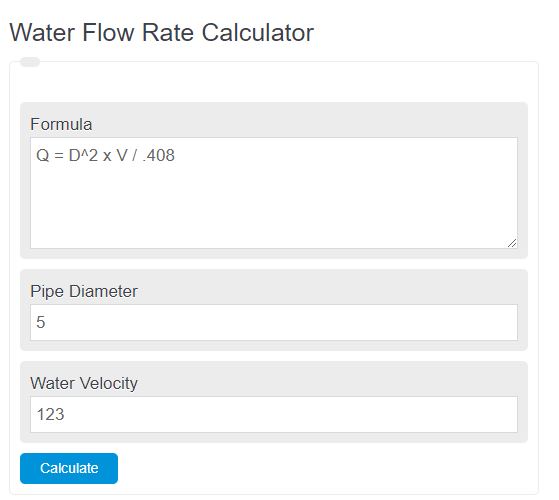

To calculate the flow rate, one can use several formulas, each applicable to different scenarios or types of flow. The most basic formula for flow rate is:

[ Q = A \times v ]

where: - ( Q ) is the flow rate, - ( A ) is the cross-sectional area of the pipe or conduit through which the fluid is flowing, - ( v ) is the velocity of the fluid.

This formula assumes a steady, laminar flow through a cylindrical pipe, which is an idealized scenario. Real-world applications often involve more complex flow regimes, including turbulent flow, and may require more sophisticated calculations.

Calculating Flow Rate in Different Scenarios

1. For a Pipe with a Known Diameter and Fluid Velocity:

If the diameter of the pipe is known, the cross-sectional area ( A ) can be calculated using the formula for the area of a circle:

[ A = \pi \times \left( \frac{d}{2} \right)^2 ]

where: - ( d ) is the diameter of the pipe.

Thus, the flow rate formula incorporating the diameter is:

[ Q = \pi \times \left( \frac{d}{2} \right)^2 \times v ]

2. For a Rectangular Conduit:

For a rectangular conduit, the cross-sectional area is calculated as:

[ A = w \times h ]

where: - ( w ) is the width of the conduit, - ( h ) is the height of the conduit.

So, the flow rate formula becomes:

[ Q = w \times h \times v ]

3. For Flow Through an Orifice or Nozzle:

The flow through an orifice or nozzle can be more complex due to the change in pressure and velocity as the fluid passes through the constriction. The flow rate in such cases can be estimated using:

[ Q = C_d \times A \times \sqrt{2 \times \Delta P / \rho} ]

where: - ( C_d ) is the discharge coefficient, which accounts for energy losses, - ( A ) is the area of the orifice, - ( \Delta P ) is the pressure difference across the orifice, - ( \rho ) is the density of the fluid.

Practical Considerations

In practical applications, calculating flow rate is crucial for various reasons, including: - Designing Pipelines: To ensure that the pipeline can handle the required volume of fluid without significant loss of pressure or efficiency. - Operation and Maintenance: Monitoring flow rates can help in detecting leaks, blockages, or other issues within the system. - Energy Efficiency: Optimizing flow rates can lead to significant energy savings in pumping systems.

Tools and Software for Flow Rate Calculations

There are numerous tools and software available that can aid in calculating flow rates for different scenarios, including: - Spreadsheets: Microsoft Excel or Google Sheets can be used to create custom calculators based on the formulas mentioned above. - Specialized Software: Programs like Autodesk AutoCAD, SolidWorks, or specific hydraulic and pneumatic simulation software can provide more detailed and accurate calculations, taking into account various factors like friction, viscosity, and turbulence.

Conclusion

Calculating flow rate is a critical aspect of engineering and scientific applications, requiring an understanding of the fundamental principles of fluid dynamics. By applying the right formulas and considering the specific characteristics of the fluid and the conduit through which it flows, accurate calculations can be made to design, operate, and maintain efficient systems. Whether using basic mathematical formulas or sophisticated software, the goal is to ensure that the fluid flow meets the requirements of the application, be it in industrial processes, water supply systems, or any other field where fluid movement is crucial.

What is the formula for calculating flow rate in a pipe?

+The basic formula for flow rate is Q = A * v, where Q is the flow rate, A is the cross-sectional area of the pipe, and v is the velocity of the fluid. For a circular pipe, the area can be calculated as A = π * (d/2)^2, where d is the diameter of the pipe.

How do you calculate the flow rate through an orifice or nozzle?

+The flow rate through an orifice or nozzle can be estimated using the formula Q = C_d * A * sqrt(2 * ΔP / ρ), where C_d is the discharge coefficient, A is the area of the orifice, ΔP is the pressure difference across the orifice, and ρ is the density of the fluid.

What are some practical considerations for calculating flow rate in real-world applications?

+Practical considerations include designing pipelines to handle the required volume without significant pressure loss, monitoring flow rates for operation and maintenance, and optimizing flow rates for energy efficiency.

What tools and software are available for calculating flow rates?

+Available tools include spreadsheets like Microsoft Excel or Google Sheets for custom calculators, and specialized software like Autodesk AutoCAD or specific hydraulic and pneumatic simulation programs for more detailed calculations.

Why is calculating flow rate important in engineering and scientific applications?

+Calculating flow rate is crucial for designing, operating, and maintaining efficient systems, ensuring that the fluid flow meets the application’s requirements, whether in industrial processes, water supply systems, or other fields where fluid movement is critical.